2D and 3D TEM for quantifying soot nanostructures

- Abstract number

- 422

- Event

- European Microscopy Congress 2020

- DOI

- 10.22443/rms.emc2020.422

- Corresponding Email

- [email protected]

- Session

- PSA.5 - Nanoparticles & Catalysts

- Authors

- Dr Michael Fay (1), Mr Sebastian Pfau (1), Mr Ephraim Haffner-Staton (1), Dr Antonino La Rocca (1)

- Affiliations

-

1. University of Nottingham

- Keywords

Soot, nanoparticles, HRTEM, fringe analysis, tomography

- Abstract text

Accurate characterisation of soot nanostructures is of particular interest for their impact on human health [1][2], the wider environment [3], and also engine efficiency [4]. With the recent wide introduction of direct injection systems for gasoline engines [5], accurate analysis of soot emissions is needed, for example to optimise particulate filters.

Full analysis of both the agglomerate morphology and the particle nanostructure are required to understand and control soot. For example, understanding the effects and mitigation of soot in lubricating oil requires knowledge of both the soot morphology, which affects the viscosity of the oil and thus overall engine performance, and the nanostructure of the soot, which influences the interaction of the soot with oil additives and thus the anti-wear properties of the oil.

TEM is a well-established method for analysis of soot nanostructures. However, for accurate analysis from this technique a number of issues have to be carefully considered, including small sampling number of particles; potential for altering structures during TEM sample preparation; sensitivity of measured parameters to microscope operating conditions; potential for misinterpretation of complex 3D structures from 2D images.

Analysis of the particle nanostructure is required to provide information on active carbon edge sites and reactivity. HRTEM analysis is a commonly used method for measuring structural parameters such as fringe length, tortuosity, and separation distance via a range of mathematical approaches for image analysis. However, obtaining consistent values derived from this process require careful and consistent selection of both instrument settings and filtering parameters for image analysis. [6]

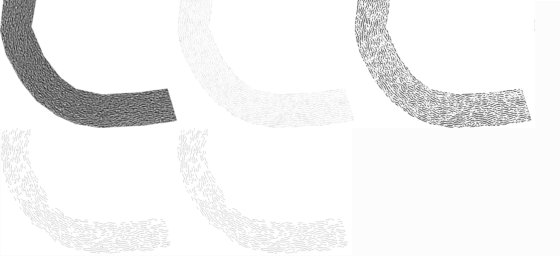

Figure 1. Fringe length analysis steps – Raw HRTEM images, inverted and cropped to ROI; After CLAHE, Gaussian blur, White top-hat transformation, and another Gaussian blur (in this order); After threshold binarization; After skeletonisation, removal of cropped fringes and short fringes (<0.4nm); Final nanostructure after cleaning up (resolving branched fringes)

A typical filtering of a HRTEM region is shown in Figure 1. Operator factors prior to this point include the defocus used, selection of the particles for imaging, and selection of the suitably thin region of the particle for fringe length analysis. Processing images in this way involves the careful choice of a number of parameters, and small variations in these filtering parameters can have a visible effect on the structural parameters obtained from HRTEM analysis. An example is shown in Figure 2, showing the sensitivity of a region from Figure 1 to varying the Gaussian filter parameters.

Figure 2. Variation with Gaussian filters, (a) 1.0, (b)2.0 and (c)3.0 pixels from a selection of the same region as figure 1

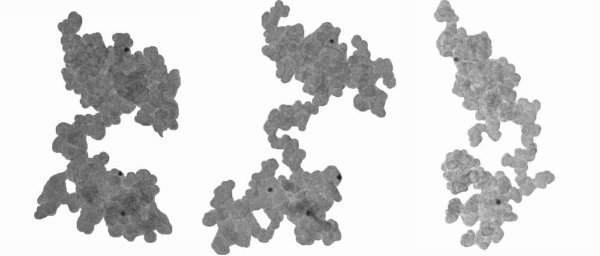

The limitation of analysis of a complex 3d nanostructure from a 2D projection can be overcome by tomographic reconstruction, albeit at the cost of significantly reducing the number of samples possible to analyse in a given time, and potentially increasing the amount of sample preparation necessary e.g. for particles with oil contamination requiring a region to be sufficiently clean for multiple image acquisitions. [7]. TEM tomographic reconstruction is highly useful to analysis of the agglomerate morphology on soot nanoparticles, but is also susceptible to variation due to choices made in acquisition and analysis. Factors that can affect the end results from 3D tomographic reconstruction include the method of selection of particles for tilt series acquisition, tilt step size and total range, reconstruction methods used, and parameters used in creating a 3d model from the tomographic reconstruction. Where samples for analysis may contain soot particles that are produced under many different operating conditions, for example soot in oil from combustion in internal combustion engines, increasing the number of soot nanoparticles analysed becomes important for statistical analysis. It thus becomes important to consider which compromises in some of 3D acquisition and tomographic reconstruction steps may be more optimal - e.g. reducing tilt step size to allow tilt series of more nanoparticles to be analysed in a given amount of microscope time, and potentially compromising on segmentation steps to maximise automation of the process while maintaining sufficient control over reconstruction errors and artefacts to obtain trustworthy data. With the advent of faster detectors and improved algorithms, semi-automated and automated 3D TEM has the potential to become a powerful too to regularly and accurately characterise the structures in soot particles. Such characterisation is essential to understand how the structure effects the properties of soot and soot containing fluids, and the extent to which controlling these features can effect these properties.

Figure 3. Three orientations of a 3D reconstruction of flame generated soot. Careful analysis of 3D reconstruction can reveal the structure of features such as bridges and cavities that cannot be fully understood from 2D projections, but which can have significant effects on the properties, e.g. the viscosity of soot containing oil.

Conclusions

HRTEM analysis of fringe lengths is highly sensitive to a number of operator and analysis selections, for example the defocus used. This gives the potential that variation between samples could in some cases be inherently less than variation between the individuals performing image acquisition and analysis unless a thorough, open, and reproducible process is used.

2D image derived parameters such as volume, surface area, and circularity show a significant deviation from values obtained by tomographic reconstruction. Tomography also allows complex morphological structures to be identified, but also has a number of decision steps during acquisition and analysis that can alter the final values obtained. Optimisation of this process can allow semi-automated and potentially automated data acquisition and reconstruction, that will allow us to gain deeper insight into the nature, effects, and control of the structure of soot particles.

- References

[1] DM Broday, R Rosenzweig, J. Aerosol Sci., 42 (6) (2011), pp. 372-386,

[2] G Oberdörster et al, Inhal. Toxicol., 7 (1) (1995), pp. 111-124,

[3] X Mari, et al. Glob. Biogeochem. Cycles., 28 (7) (2014), pp. 662-678,

[4] S George et al Tribol. Int. 40, (2007) 809–818.

[5] A Hula et al. No. 2014-01-0781. SAE Technical Paper, 2014.

[6] SA Pfau, A La Rocca, MW Fay, Combustion and Flame 211, 430-444

[7] E Haffner-Staton, A La Rocca, MW Fay - Journal of microscopy, 2018 270.3 (2018): 272-289.

[8] This work was supported by the Engineering and Physical Sciences Research Council through the scholarship provided by EPSRC DTG Centre in Complex Systems and Processes for Ephraim Haffner-Staton and the scholarship provided by EPSRC Thematic Programme in Low-Dimensional Materials and Interfaces for Sebastian Pfau [grant numbers EP/ M506588/1 and EP/N50970X/1 respectively]. The authors thank the Nanoscale and Microscale Research Centre (nmRC) for providing access to instrumentation.