Development of high-temperature electrochemical TEM and its application on solid oxide electrolysis cells

- Abstract number

- 925

- Event

- European Microscopy Congress 2020

- DOI

- 10.22443/rms.emc2020.925

- Corresponding Email

- [email protected]

- Session

- PST.6 - In-situ and in-operando microscopy

- Authors

- Søren Bredmose Simonsen (1), Fabrizio Gaulandris (1, 5), Simone Sanna (1), Waynah Lou Dacayan (1), Christodoulos Chatzichristodoulou (1), Kristian Mølhave (3), Jakob Birkedal Wagner (3), Wenjing Zhang (2), Yunzhong Chen (1), Shun Muto (4), Luise Theil Kuhn (1)

- Affiliations

-

1. DTU Energy

2. DTU Environment

3. DTU NanoLab

4. Nagoya University

5. Solid Power Group

- Keywords

electrochemistry, solid oxide electrolysis cell, solid oxide fuel cell, electrochemical impedance spectroscopy

- Abstract text

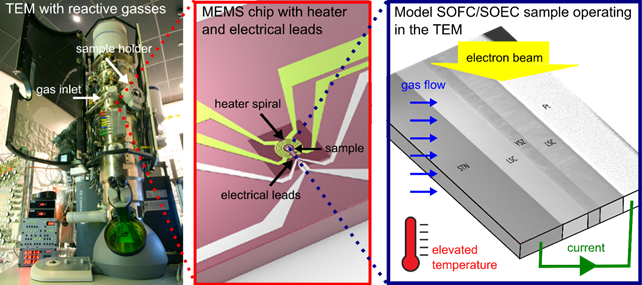

Solid oxide electrolysis cells (SOEC) is a promising technology for efficient green energy storage by conversion of electrical energy to chemical energy [1]. SOEC operate in reactive gasses (O2, H2O, CO2) at high temperatures (≥ 800°C), which makes it challenging to study them via in situ TEM. In addition, SOECs are composed of hard and brittle ceramics and can be difficult to thin for electron transparency and manipulate without breaking. However, post mortem electron microscopy does not give direct insight into time, temperature and electrical potential dependencies of cell degradation, and in situ characterization is therefore needed.

We are transforming a TEM into a generic high-temperature electrochemical workstation for SOEC materials. In particular, we focus on the combination of TEM and electrochemical impedance spectroscopy (EIS). EIS is today one of the most powerful characterization methods for distinguishing electrochemical resistances for different processes (ion transport, gas diffusion, catalytic reactions etc.) [2].

Here we present different approaches for designing high-temperature electrochemical TEM experiments. In one study, we are using a model SOEC composed of materials commonly used in state-of-the-art SOECs, i.e. La0.6Sr0.4CoO3-δ (LSC) electrodes and a Zr0.8Y0.2O2-δ (YSZ) electrolyte. The cells are prepared by pulsed laser deposition (PLD). In another study the samples are electrospun LSC, YSZ and gadolinia-doped ceria (CGO) nanofibers representing electrode and electrolyte materials in an SOEC.

For the experiments, an ETEM is used in combination with custom-made and commercial heating/biasing TEM holders and a potentiostat and impedance analyzer for measuring I-V response as well as EIS data. Observations include segregation and grain formation for single crystal LSC electrodes, which accelerated as a function of temperature, and was promoted by the presence of O2 compared to vacuum [3]. The oxidation state of Co in LSC near the LSC-YSZ interface increases at temperatures above ca. 400°C both in O2 and even in vacuum. Structural degradations are observed both as a response to heating and applied polarization.

Acknowledgment

This project has received funding from the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation programme (grant agreement No 850850)

The Danish Council for Independent Research is acknowledged for providing funding for the project In situ transmission electron microscopy on operating electrochemical cells – TEMOC grant no. DFF – 4005-00247.

Fig. 1: Illustration of one approach for high-temperature electrochemical TEM

- References

[1] N.Q. Mitili, M.B. Mogensen, Reversible Solid Oxide Fuel Cell Technology for Green Fuel and Power Production, Interface. 22 (2013) 55–62.

[2] M.J. Jørgensen, S. Primdahl, M.B. Mogensen Characterization of composite SOFC cathodes using electrochemical impedance spectroscopy Electrochimica Acta, 44 (1999) 4195-4201

[3] F. Gualandris, S.B, Simonsen, J.B. Wagner, S. Sanna, S. Muto, L.T. Kuhn In Situ TEM Analysis of a Symmetric Solid Oxide Cell in Oxygen and Vacuum–Cation Diffusion Observations ECS Transactions 75 (2017) 123-133.